Services ESAB EAGLE 2000 Retrofit - Dual Process System

45A PMX Galvanised plate rider + Driven Height controlled Z axis 130A UltraCut XT.

The ESAB machine had an intermittent fault on the older ESAB controller. The machine has now been given a new lease of life with a fully new control system, 130A plasma power source and a new Z axis system for the heavy cutting and the lighter galvanised cutting.

CR PLASMA fitted a full retrofit to the machine updating the system with the following

New driven Z axis - with a new UltracutXT130

Plate rider Z axis system for the Galv - running existing 45XP

New Hoses and Cables on all machine functions

New Modern AC servo motors.

ESAB EAGLE 2000 CR PLASMA RETROFIT Cutting 15mm Stainless Steel

Running a driven Z axis with full height control, the system is cutting 15mm Stainless Steel with the Thermal Dynamics UltraCut XT 130A power supply. The system runs Water Mist and Nitrogen to keep oxygen away from the cutting process.

Check out how clean the edge is raw from the plasma process!!

ESAB EAGLE 2000 CR PLASMA RETROFIT Cutting 15mm Mild Steel

Full height control of the torch to manage 130A’s of power from the UltraCut XT. The system is running Oxygen and Air for full high definition cutting of Mild Steel.

ESAB EAGLE 2000 CR PLASMA RETROFIT Cutting 0.8mm Galvanised Steel

The dual process retrofit allows the ESAB under CR PLASMA control to cross over between a plate rider running a 45A XP from Hypertherm, and the fully driven Z axis running the 130A UltrCut XT.

Check out the plate rider in action in the video. This is the best way to manage the galvanised steel as it buckles and twists as its cut.

ESAB EAGLE 2000 CR PLASMA RETROFIT Cutting 15mm Alminium

Simialr to cutting Stainless Steel, cutting Alminium benfits from the water mist and nitrogen cutting. The water mist vapour here generates some nice drama in the video!!

ESAB EAGLE 2000 CR PLASMA RETROFIT Cutting 1mm Alminium

When cutting alloy and stainless with the 45 XP plasma on the plate rider - this results in air being in the cut process and causes a black edge. Shown here is the driven Z axis cutting 1mm alminium with the water mist and nitrogen process - and also using height control.

CR PLASMA Retrofit: Esab EAGLE

Transforming Legacy Machines into Modern Powerhouses

The CR PLASMA team has successfully revitalized the Esab EAGLE, a 4x2 meter CNC machine, with cutting-edge plasma technology, turning a once-intermittently failing machine into a precision-driven, high-performance solution.

Key Retrofit Enhancements

Core System Upgrades:

Replaced the original outdated ESAB controller with a robust CR PLASMA control system featuring non-proprietary, off-the-shelf components for easy maintenance and replacement.

Installed a high-spec PC, touch screen, and backup power supply, creating a modern, user-friendly interface.

Mechanical Retrofitting:

Retained the original frame, rails, and gearboxes while replacing the X and Y-axis servo motors and fitting new pinions with special adapter plates for compatibility.

Upgraded homing induction sensors, end-of-travel switches, and all cables for enhanced reliability.

Z-Axis and Dual-Process Functionality:

Added a new Z-axis torch lifter system for precise height control.

Integrated a dual-process system:

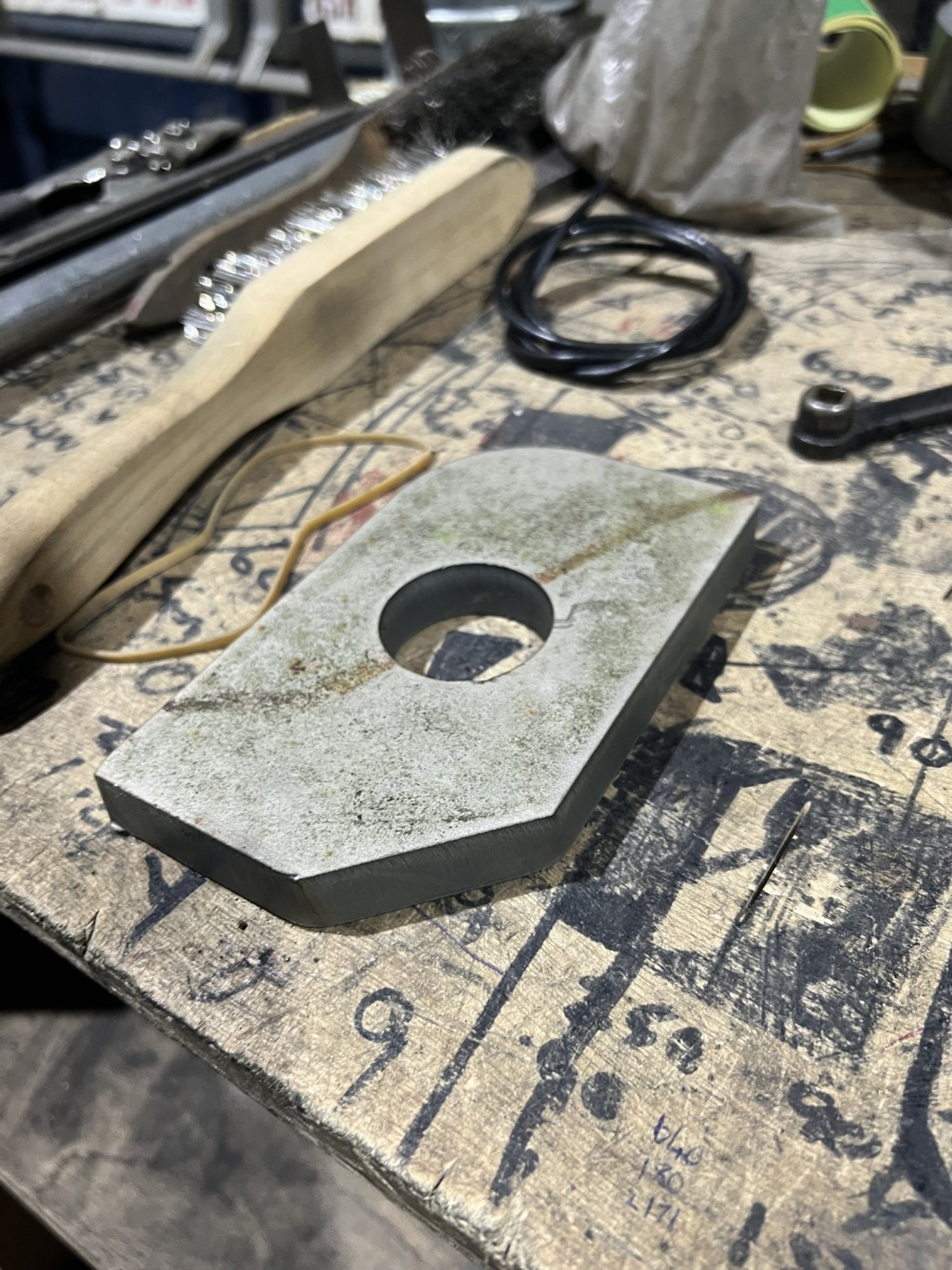

Plasma Duct Cutting: A plate rider mechanism ensures efficient handling of buckling galvanized steel sheets.

Advanced Plasma Cutting: Supports up to 25mm mild steel cutting using the Thermal Dynamics UltraCut XT.

Enhanced Power Source Integration:

Equipped with a 45 XP power source for galvanized materials and a 130-amp Thermal Dynamics Ultra Cut XT for versatile cutting, including stainless steel up to 15mm thick, aluminum up to 15mm thick, and mild steel up to 25mm thick.

Operational Benefits

The time frame for retrofitting can be in the order of weeks, not months.

Retains workshop setup, minimizing disruption and cost.

Ensures exceptional mechanical precision (<0.03 mechanical backlash).

Delivers the performance of a brand-new machine at a fraction of the cost.

Supply of high-spec PC allows integration into existing IT systems and compatibility.

Efficiency and Longevity

The retrofit retains the Esab EAGLE’s robust design, leveraging its oversized, durable components while integrating state-of-the-art plasma technology. The system now operates smoothly, accurately, and, more importantly, reliably and with full support.